Industries

-

ACHE Sprockets

-

Agricultural Equipment

-

CNC Machinery

-

Industrial Equipment

-

Machine & Conveyor Belts for Packaging Industry

-

Material Handling

-

Oil & Gas Power Transmission Products

-

Pulleys & Timing Belts for the Robotics Industry

-

Timing Belts & Components for 3D Printers

-

Timing Belts & Pulleys for Vending Machines

-

Warehouse Automation

-

Medical Industry

B&B Manufacturing® has expanded our ACHE Sprocket offering to allow for possible reducer elimination or reduction.

Taper-Lock® ACHE sprockets have a longer bore length in order to withstand high torque. They are designed with extra mass around the shaft so that the sprockets remain stable. However, B&B's ACHE offering is mainly QD® bushed. The QD® design transmits the required torque without unnecessary, additional weight around the shaft. This provides the benefits of reduced bearing and overhung loads. Larger sized sprockets are offered in HTD® to ensure proper chordal action. Chordal action is the rise and fall of the belt tooth in and out of the sprocket teeth. Without correct belt-sprocket tooth engagement, products can get caught, slip, or fall between the belt and sprocket. ACHE Sprockets are used in cooling and condensing in industries like: Oil and Gas production, processing, and transport; HVAC; Power generation, and more.

Why B&B Manufacturing®?

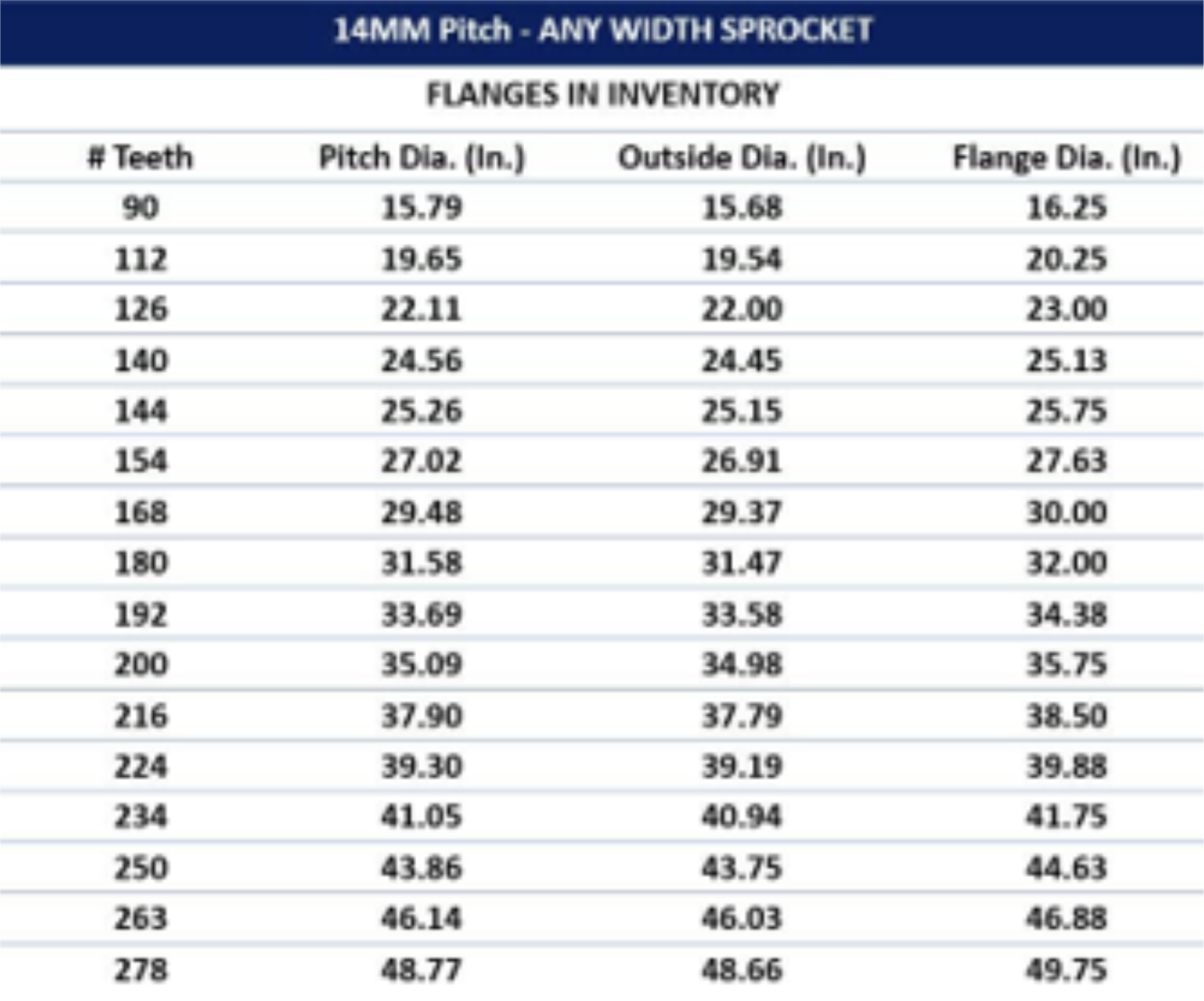

Knowledge of ACHE Sprocket flanging requirements

- When 2 Point Drives have center distances that are greater than 8x the diameter of the smaller sprocket, both sprockets should be flanged on both sides.

- On vertical drives, 1 sprocket should be flanged on both sides, and all the other sprockets in the system should be flanged on the bottom side only.Reduced Acquisition Costs

- B&B Manufacturing® holds sprocket inventory in La Porte, IN (no excess freight charges from marketer to machine shop to attach flange(s)).

- We manufacture flanges in-house (less delays since there is no wait on outside sources to import the flanges, minimizing costs).

We offer Nickel Plating for ACHE (Fin-Fan™) Pulleys/Sprockets.

Why? Because rust, corrosion, or wear of the sprocket can become severe enough to change the sprocketgroove shape, which will have a negative impact on belt life for all belt constructions.

Nickel Plating Process

Maximum Nickel-Plating Thickness : 0.001 – 0.0015”

Electroless Nickel Plating combines resistance to wear and corrosion with excellent adherence to all metals.

B&B Manufacturing follows ASTM B733 Type IV SC3 nickel plating pulleys/sprockets.

Type IV: 5-9% phosphorous (medium phosphorous)

SC3: Moderate Service 0.001 in minimum

Flanges are nickel plated at the same time if required.

Q.D.®, Taper-Lock®, and Double Split Taper bushings available for nickel plating also.

Sizing Available from 14mm sprockets from stock.